Content

RO Water Treatment

Update: 15/11/2024

Share:

What is an Industrial RO Water Filtration System?

The industrial RO (Reverse Osmosis) water filtration system consists of membranes connected in series by pipelines. When water passes through the RO membrane, it retains impurities, bacteria, heavy metals, and produces purified water to meet the needs of factories, enterprises, and hospitals. Even bottled filtered water is created using this system.

.webp)

The machine utilizes the principle of reverse osmosis, a method that is completely different from the simple filtration process of conventional high-capacity water filters. It eliminates up to 99% of harmful minerals and chemicals.

Key Advantages of Industrial Water Filtration Systems

As mentioned earlier, industrial water filtration equipment significantly saves costs compared to purchasing bottled purified water. Additionally, it saves storage space for bottles after production.

- Cost-saving.

- Space-saving.

- Provides clean water.

- Ensures sufficient water supply for industrial and daily use.

Moreover, using this filtration system provides pure water that is safe for public health.

Structure of an Industrial Water Filtration System

The industrial water filtration system consists of four main components:

1. Pre-Filtration Unit

This is the initial stage of the filtration process. Incoming water sources such as well water or tap water are pre-processed, meaning that water is treated to remove impurities, ions, and heavy metals using a high-pressure pump and industrial water filter columns (also known as pre-filter columns).

.webp)

Each filter column serves different functions:

- Column 1: Removes suspended solids or heavy metals.

- Column 2: Eliminates harmful substances like ammonia (NH3), sulfur (S), and phosphorus (P).

- Column 3: Converts hard water to soft water by reducing ions such as Ca2+, Mg2+ to acceptable levels.

2. RO Filtration Unit

Water processed in the first unit is sent to the RO membrane filter.

RO Membrane Filters remove up to 99% of harmful impurities, viruses, and bacteria. The more filtration stages, the purer and higher the water quality.

3. High-Pressure Pump

To ensure smooth operation of the RO membrane, sufficient water pressure is required. This role is performed by a high-pressure pump, also known as an RO pump.

When the pump operates, it generates enough pressure to expedite the osmosis process, reaching up to 200 - 230 PSI and functioning continuously 24/7.

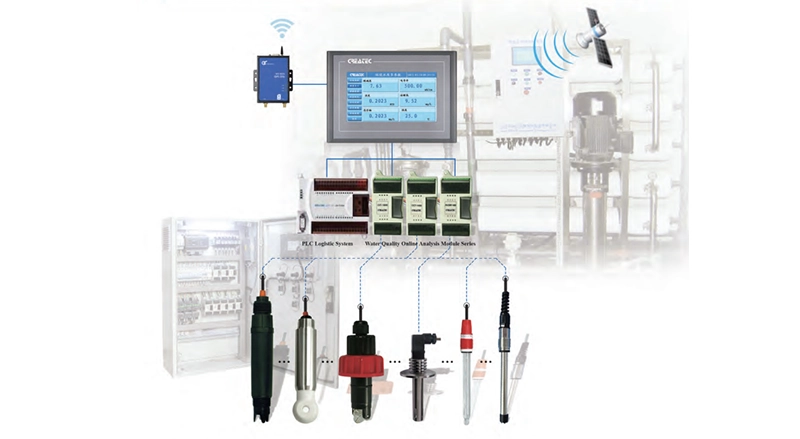

4. Control Unit

This crucial system includes electronic circuit boards, input-output indicators, and pressure gauges.

Thanks to the control system, the filtration process is fully automated. It automatically cleans the membrane and reports results on a screen, making it convenient to monitor the entire system.

Price List for Large-Capacity Industrial RO Water Filtration Systems

Currently, the market offers various suppliers of industrial filtration systems with diverse prices. To help customers estimate their budget, we provide the following price list:

| No. | Product | Reference Price (VND) |

| 1 | Semi-industrial water filter 30l/h | 7,000,000 |

| 2 | Semi-industrial water filter 50l/h | 8,500,000 |

| 3 | RO Semi-industrial water filter 80l/h | 10,000,000 |

| 4 | Industrial RO water filter 100l/h | 13,500,000 |

| 5 | Industrial water filter 150l/h | 30,000,000 |

| 6 | Industrial RO system 250l/h | 41,000,000 |

| 7 | RO Water Filter 500l/h | 52,000,000 |

| 8 | Industrial RO System 1000l/h | 110,000,000 |

Update: 15/11/2024

Share:

Related projects

Water Filter Columns

Water Filter Columns

Water Filtration Membranes

Water Filtration Membranes

Control Valves

Control Valves

Water Filter Cartridges

Water Filter Cartridges

Water Pumps

Water Pumps

Water Filtration Equipment

Water Filtration Equipment

Water Filtration Components

Water Filtration Components

Water Filtration Materials

Water Filtration Materials

Heat Pump Water Heaters

Heat Pump Water Heaters

Products

Products  Solutions

Solutions  Project

Project  News

News